APAGCoSyst supplies electronics and lighting components for the automotive, medical, and industrial sectors. The experienced research and development team at APAGCoSyst specializes in bringing creative ideas to life by designing, developing, and producing unique and complex goods from our state-of-the-art production facilities. We are driven by our core values in our CREDO – the 5Cs: Consideration, Commitment, Creativity, Cohesion, and Character. They drive us to deliver excellence on every project we participate in.

Quality means delivering products and services customized to exceed the expectations of our customers, within the agreed delivery time and at an optimum price-performance ratio. We understand that each customer has different needs, and our concept of quality includes providing competent, professional, and reliable service to our external partners, in addition to adhering to our own quality standards in line with our CREDO for development, production, and customer service.

As a contract manufacturer operating in strict adherence to the highest quality standards used by the automotive and medical sectors, we match virtually any quality requirement for our customers.

For example, we inspect PCBs at all stages, including proof of compliance with purchase orders regarding uniform appearance, legible text, quality of metallization, dimensions, hole alignment, adhesion strength, and electrical testing. APAGCoSyst’s quality experts also make certain that PCBs are free from processing defects, cosmetic flaws, fine cracks, nicked edges, and more.

Exceptional quality is maintained through 100% regular in-process testing. By doing so, we ensure our processes, production sites, and facilities are always up to date.

When possible, we strive to set new standards for quality at every opportunity.

Sustainability Commitments

As a global company, APAGCoSyst is aware of its responsibilities. This applies to our own processes as well as to our cooperation with suppliers and our effect on society at large.

APAGCoSyst is certified according to ISO 14001. This involves comprehensive measures necessary to ensure responsible use of energy and resources. We are convinced that making the most of the various possibilities available to ensure sustainable business operations will allow us to preserve a sound environment worth living in and align our actions accordingly.

APAGCoSyst always exceeds legal requirements regarding environmental protection, as well as occupational health and safety, with continuous improvement initiatives including all employees, services, production, and business processes.

We are also ensuring standards in our supply chain by implementing processes to continuously review our supply chain with regard to the sourcing of conflict minerals. Nearly 100 suppliers were screened for use of conflict minerals.

APAGCoSyst’s quality and environment policy is strictly based on our values.

Related documents:

Development Standards

We follow numerous development standards that facilitate high quality design and production, such as:

- IBM DOORS®. IBM’s Dynamic Object-Oriented Requirements Systems (DOORS) allows us to communicate with all project stakeholders in one place, ensuring that all engineering requirements are up to date, understood, and met.

- Polarion. This application lifecycle management (ALM) allows us to develop and verify software tools used to design electronic assemblies and printed circuit boards.

- ISO 26262.This standard guides the development of electrical systems in road vehicles, ensuring that they function safely.

- Agile development.We’ve broken down silos in our organization, facilitating cross-team collaboration at every level to bring knowledge and agility to every project.

- Automotive SPICE®.APAGCoSyst uses ISO/IEC 15504, more commonly known as the Automotive SPICE process assessment model (PAM), to manage project tasks and suppliers in the most efficient way possible.

Production Standards

At APAGCoSyst, our production operations are guided by stringent industry and internal quality standards. These include:

- ISO 26262. This standard guides the development of electrical systems in road vehicles, ensuring that they function safely.

- IPC 610 Level 3. IPC 610 is a standard for building electronic assemblies. APAGCoSyst builds electronic assemblies to IPC 610 Level 3, the highest of these standards.

- IPC 7711. This certification provides standards for reworking or repairing electronic assemblies and printed circuit boards.

- Smart Manufacturing processes:

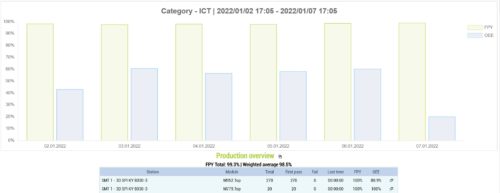

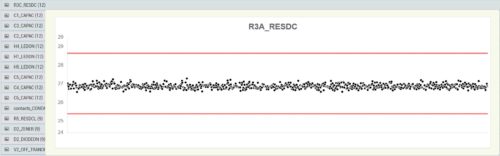

- Automatic KPI monitoring: Our MES system provides customizable digital boards for every sector of our manufacturing sites so no information is ever lost

- Interlocking and specific operation-level traceability system: DMX codes scanned on each single product ensure that only certified-operational completed parts to produce to the following production steps, and can, in the rare event of errors, trace the issue at the component level. This allows us to maintain our historically low defect PPM levels in the single digits.

- Real-time Production Warning: When actual production will deviate from the set target and produce abnormality, the system will give real-time feedback and alerts to technicians and managers.

- ESD flooring, temperature and humidity control with Real-Time Warning, and pressurization for dust repulsion. Our assembly lines are designed to minimize human manipulation.

- Automatic KPI monitoring: Our MES system provides customizable digital boards for every sector of our manufacturing sites so no information is ever lost

Commitment to Product Quality

APAGCoSyst offers a high level of component traceability and process interlocking. We troubleshoot problems immediately because we print unique QR codes for every component we send out.

With stringent quality assurance practices in place, customers may rest assured that APAGCoSyst will never lower our quality standards to cut costs. Every module is tested before shipping.

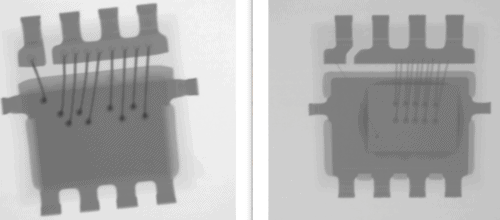

Fraudulent/Counterfeit Electronic Parts avoidance:

In case APAG Cosyst is requested to buy components from the broker market, to purchase old date codes components, or receives these components from its customer, APAG Cosyst will implement its Broker Component Incoming procedure, based on AS6081 and IDEA-STD-1010 (including checking of labels, marking, decapsulation or X-ray and comparison with its library of original labels/components, …) and will not start production without the approval of its customer.

Original component vs. Fake component

APAG Corporate policy for use of unauthorized sources

We serve numerous automotive OEMs and Tier 1 suppliers across Europe, North America, Japan, and China. Our products can be found in cars and motorcycles from Porsche, Audi, Volkswagen, Bentley, Bugatti, Lamborghini, Ducati, BMW, Mini, Rolls Royce, Mercedes-Benz, Volvo, Jaguar, Land Rover, Cadillac, Alfa Romeo, Jeep, Maserati, Renault, and Nissan. APAGCoSyst also provides innovative electronics solutions for customers in other industries, such as agriculture, industrial, medical, and more. To see how our advanced electronics design and fabrication capabilities can serve your application, please contact us today.

Certifications

To view downloadable PDF of one of our various industry certifications, please click the relevant link: