What Is an Integrating Sphere

How do engineers measure the total light output from an LED or laser, accurately and without angular bias?

As optical technology advances across industries like automotive, aerospace, and electronics, the need for precise, standardized light measurement becomes increasingly critical. One instrument that has become indispensable in labs and production lines alike is the Integrating Sphere.

But what exactly is it, how does it function, and why is it so crucial to accurate optical measurement?

Understanding the Integrating Sphere

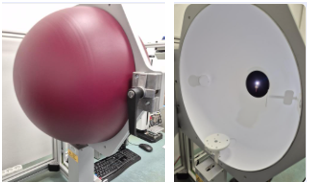

An Integrating Sphere, also known as an Ulbricht Sphere, is a hollow spherical device coated internally with a diffusely reflective material such as barium sulfate or PTFE (polytetrafluoroethylene). Its unique structure allows light entering the sphere to undergo multiple diffuse reflections, effectively scattering the light uniformly across the inner surface.

This uniform distribution ensures that light measurements are independent of direction, shape, or beam angle, an essential feature when measuring total luminous flux, spectrum, or color uniformity.

How Does an Integrating Sphere Work?

When a light source is introduced into the sphere, either placed inside or directed through an entry port, the internal coating diffuses the light evenly in all directions. A detector, such as a spectroradiometer or photodiode, is typically mounted on the sphere wall to collect and measure this evenly distributed light.

This setup enables precise, repeatable measurement of:

- Total luminous flux

- Spectral power distribution

- Color temperature

- Radiant power

Because it removes angular dependence, this method is ideal for evaluating LEDs, laser diodes, and miniature light modules where beam direction varies.

Check out Wikipedia for more information about the principle of the use of an integrating sphere to measure the transmittance and reflectance of a test sample

Common Applications of Integrating Spheres

Integrating Spheres are widely used in:

- Automotive Lighting Validation

- LED Luminous Flux Testing

- Laser Power Measurement

- Material Reflectance and Transmittance Testing

- Color Calibration and Uniformity Checks

- Photodetector and Spectrometer Calibration

They are particularly valuable in settings where non-destructive optical testing and traceable measurement standards are required.

Benefits of Integrating Spheres in Optical Testing

Here’s why these instruments are widely adopted in both research and production:

- Accelerated Development Cycles: Internal optical validation speeds up prototype testing and shortens iteration loops.

- Enhanced Quality Control: Variations in light output are detected early during serial production, helping maintain consistency.

- Root Cause Analysis: Optical behavior can be evaluated at multiple points before and after assembly to isolate problems more effectively.

- Reduced Dependency on External Labs: Testing can be conducted on-site, reducing delays and increasing flexibility.

A Real-World Example: APAGCoSyst’s In-House Optical Testing Capability

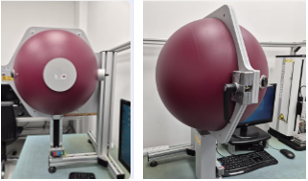

To illustrate how this technology is being applied in practice, we APAGCoSyst, a global electronics manufacturer, recently integrated a GigaHertz-Optik Integrating Sphere into its internal test lab.

This adoption underscores the growing trend of incorporating lab-grade optical tools directly into development and manufacturing environments to improve speed, accuracy, and product reliability.

Customer Benefits from Integrating Sphere-Enabled Testing

This internal capability directly benefits customers by:

- Faster project turnaround, with in-house testing eliminating delays from external validation labs

- Improved measurement accuracy and consistency, thanks to standardized testing environments

- Greater confidence in data, with results that are fully traceable and aligned with international optical testing standards

A Long-Term Investment in Quality and Innovation

As vehicle electronics become more sophisticated, precise optical performance is no longer optional—it’s expected. By investing in advanced metrology tools like the Integrating Sphere, APAGCoSyst strengthens its ability to develop, test, and validate lighting solutions with measurable quality benchmarks. This positions both the company and its clients for long-term success in a competitive and rapidly evolving industry.

For those interested in diving deeper into the technical side, visit GigaHertz-Optik’s product page or explore the Wikipedia entry on Integrating Spheres.